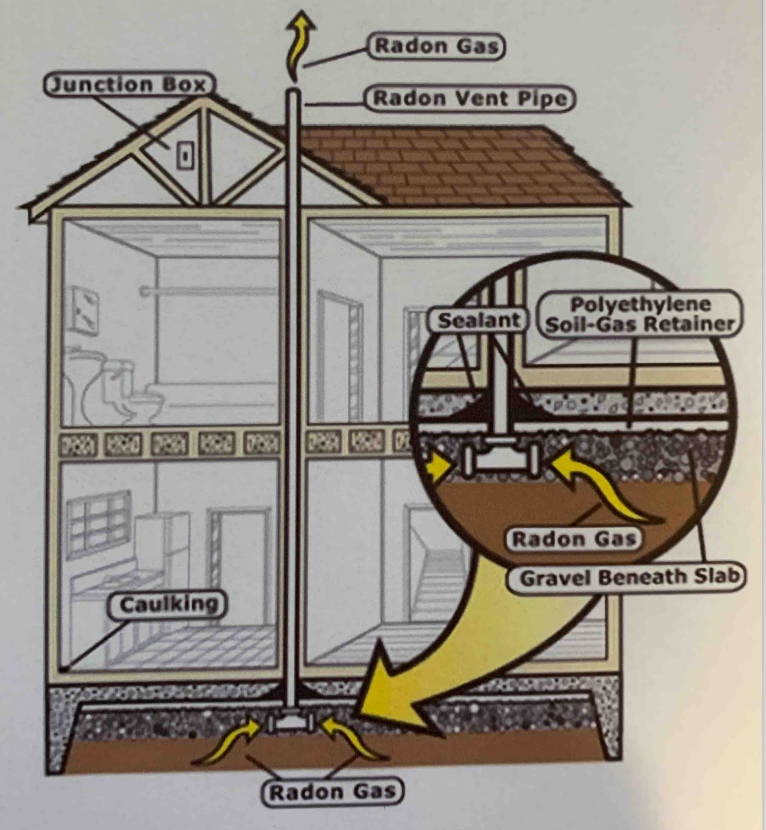

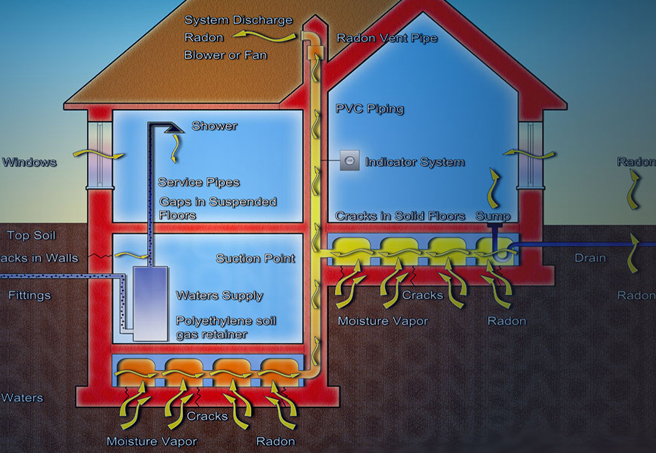

Sub Slab or Sub Slab Membrane Depressurization

“Basic Operation Principles”

A 4” in diameter hole is cut in the concrete slab, or made in the surface of the polyethylene membrane. A cavity or pocket is formed in the soil beneath the hole. A 3” PVC pipe is then set into the hole and attached to the depressurization system. This is a small network of piping that is connected to an in-line ductfan. This ductfan will be either located in the garage attic, the house attic, or mounted on the outside of the home. The in-line ductfan creates a vacuum near the hole, if not entirely under the slab, membrane, or both. The vacuum created at the hole causes Radon as well as other soil gases to move towards the suction point where it is collected and exhausted above the elevation of the highest eave on the home.

All available, or exposed Radon entry points have also been sealed or blocked, such as the sump pit lid, wall / floor joints, cracks in the floors & walls, and around any penetrations of the floor.

An Active Radon Mitigation System relies heavily on the continuos operation of the in-line ductfan. This fan is designed to run continuously throughout the year, to ensure acceptable Radon Levels.

The in-line ductfan is powered by electricity, & hardwired into the buildings electrical system. This work & material abides by all the local electrical codes.

This system requires no maintenance whatsoever. To make sure the fan is in operation, occasionally look at the U-Tube Manometer to make sure the fluid is not at an even level.